ASTM D4632 - Standard Test Method for Grab Breaking Load and Elongation of Geotextiles

ASTM D4632 is a grab test used to determine the breaking load (grab strength) and elongation (grab elongation) of geotextile fabrics. This standard is primarily used in quality control and acceptance testing labs comparing geotextiles of similar or identical structure. It is not recommended to compare uniquely structured geotextiles or for testing knitted fabrics. It is important to review ASTM D4632/D4632M-15 in order to fully understand the test setup, procedure, and results requirements.

How is the Test Performed?

The grab test is a tensile test where the central part of the specimen's width is tested to establish the "effective strength" of the fabric. The effective strength is the strength of the material at a specific width when combined with the additional strength of adjacent material. Test specimens are cut in both the machine direction and cross-machine direction, but are expected to have their results calculated separately. Specimens are cut to 101.6 mm x 203.2 mm (4 in x 8 in), with attention to the direction of the fabric.

The specimen is loaded into the grips leaving a 75 mm (3 in) separation between the jaw faces. ASTM D4632 calls for jaw faces that are at least 25.4 mm x 50.8 mm (1 in x 2 in). However, it allows for each grip to include one jaw face that is larger than the other (a modified grab test), which can be helpful in reducing the effects of specimen/jaw face alignment. The test is conducted at a speed of 300 mm/min (12 in/min) with the required results being load at break and total elongation.

Testing System

Geotextile testing requires a test system with a data rate capture high enough to measure the failure of individual fabric fibers. Because of this, KASON recommends a high tier KASON ETM Series test frame, which provides a data acquisition rate of up to 5 kHz and captures data peaks and valleys accurately at up to 2500 or 5000 points per second, respectively. For most geotextiles testing to ASTM D4632, a single column frame such as KASON's ETM503 is appropriate, as the loads rarely climb higher than 5 kN. The rapid data capture rate in KASON software allows data peaks and valleys to be captured accurately.

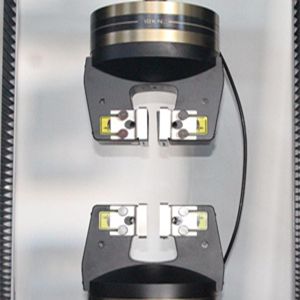

Grips

Geotextile materials tend to have coatings that may make them difficult to test without slippage or jaw breaks. KASON’s pneumatic side acting grips provide an easy, repeatable, high throughput gripping solution that allow the user to quickly fine-tune gripping pressure to avoid jaw breaks or slippage. Pneumatic side acting grips also feature KASON’s quick-change technology which allows the jaw faces to be easily changed by hand without requiring tools or pins. Since different geotextiles can require a range of different clamping surfaces, quick-change jaw faces can significantly improve throughput in labs where these materials are common.